Production Processes

Turning Process

Pipe-shaped bearing steel (special steel for bearings) is sliced into rings. The sliced rings are machined with a blade to the shape of outer and inner rings.

Heat Treating Process

Outer and inner rings are placed in a furnace and heated to achieve the required hardness and toughness for bearings.

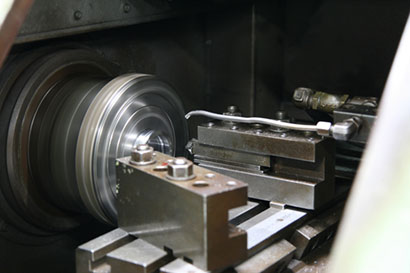

Grinding Process

A grinding wheel rotating at high speed is pressed against the workpiece to remove the material at the contact points, thereby improving the product’s accuracy.

Plane grinding process

The side surfaces of outer and inner rings are ground with a grinding wheel. This process forms the basis for all the grinding processes that follow.

Outer surface grinding process

The outer surfaces of outer and inner rings are ground with a grinding wheel. The accuracy of the outer surfaces affects the fitting, noise, and vibration when the bearing is assembled into a product.

Groove grinding process

The grooves of outer and inner rings are ground with a grinding wheel.

The groove diameters of outer and inner rings play an important role in creating a clearance in the assembly process afterwards.

Inner surface grinding process

The inner surface of inner rings is ground with a grinding wheel.

The accuracy of the inner surface affects the fitting, noise, and vibration when the bearing is assembled on a shaft.

Groove superfinishing process

The grooves of outer and inner rings are ground with a grinding wheel for superfinishing to produce a consistent roughness.

The finished surface roughness affects the fatigue life of the bearing.

Assembly Process

A clearance is ensured between the outer and inner rings. A specified number of balls are evenly placed in the clearance. Then, the retainer is assembled by swaging. After applying lubrication such as grease, the bearings are enclosed with seals or shields to prevent intrusion of water or dust.

Inspection Process

Precision inspection is conducted for finished products. This final inspection confirms that the products have no defects by checking all guaranteed specifications and appearance checks.

Packing Process

Products are packed into boxes according to individual customer requirements.

Shipping Process

The required number of products are removed from the warehouse and packaged for shipping for each customer order.